Our Blog

We Had Our Wires Crossed!

September, 2020

We had our wires crossed!

During the overhaul of our website earlier this year we missed something. We did not include our abilities to provide a key service to our customers. This has been something we have offered and provided to our customers for many years. We have added a designated spot on our website for all your Wire Harness, Cable Assembly, and Overmolding needs.

As technology has evolved many printed circuit board designs have adopted wireless capabilities. Depending on the application using wireless technology can be effective, however there are still many cases where a dependable wired connection is crucial. Wired connections offer the security, power, data transfer speeds, and overall reliability that wireless connections cannot.

When it comes to the construction of your wire needs there are a lot of things that should be considered. No matter how simple or complex your design we can support your Wire Harness, Cable Assembly, and Overmolding needs! (up to 28 gauge)

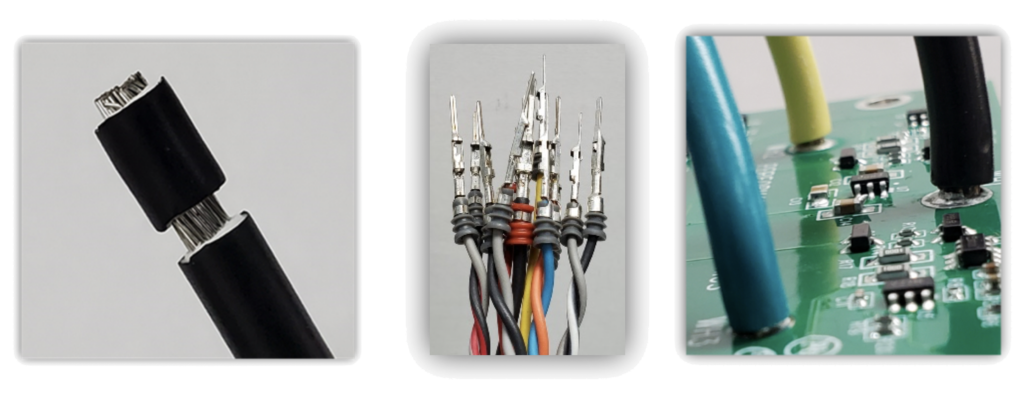

Wire Leads

We can cut to length, strip the ends, tin for soldering, crimp if needed, and solder into your PCB’s.

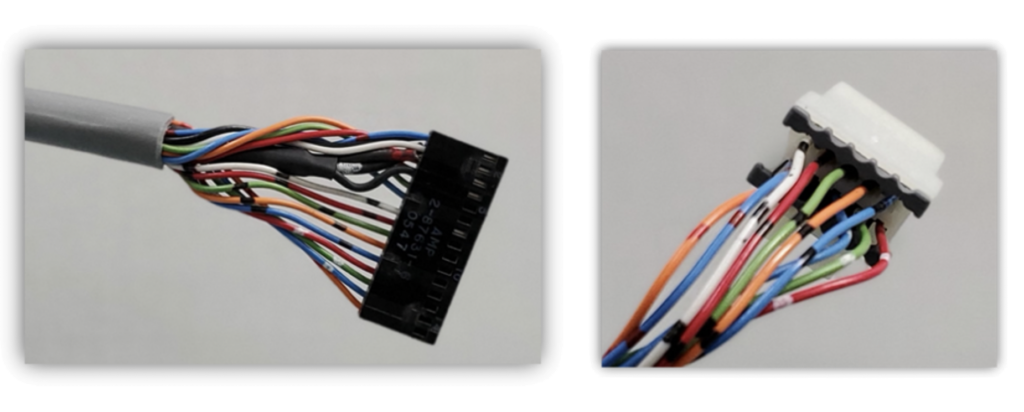

Cable Assemblies

If you need terminals added to only a few wires or connectors added to a large group of wires Spectra-Tech can produce this for you.

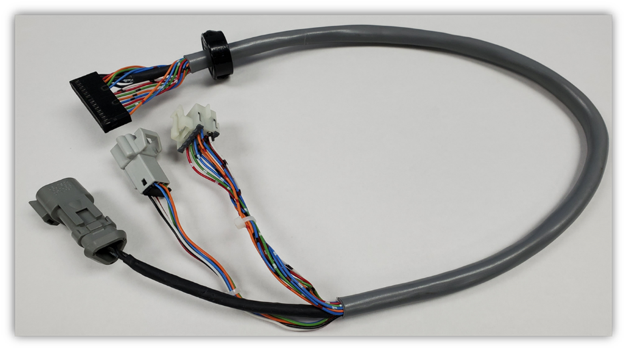

Wire Harnesses

If you need your wires or cables bundled together into a custom configuration with terminals and/or connectors allow Spectra-Tech to be your supplier.

Overmolding

Overmolds are created when two or more, different materials are combined into a single part. Overmolding is typically done to:

- Protect and simplify the product

- Improve the appearance of the final product

- Make the component water resistant

- Reduce rings and seals

- Fix sealing elements

- Alter the part’s appearance for design, safety, or identification

- Enhance durability by adding strain relief and decreasing stress on internal components

Often this includes covering an existing part with an additional material. For example, TPE (Thermoplastic Elastomer) can be molded onto a rigid plastic-coated wire using heat, pressure, and liquid silicon to seal the parts connectors. Overmolding can also add required functional elements to a finished part. Depending on the material used for the overmolding, some of the more specific overmolds purposes include:

- Sealing connectors onto wire

- Adding strain relief

- Enhancing grip

- Improving handling comfort

- Improving the look and feel

- Changing texture or color

- Streamlining appearance

Take a virtual facility tour and see why we should be your chosen manufacturer.

Contact Us